Use of Color in Models

Posted: Fri Apr 09, 2021 2:59 pm

Here's a reprint of one of my favorite articles from a couple of years ago. Model colors are essential for a lot of things.

Use of Color in Models

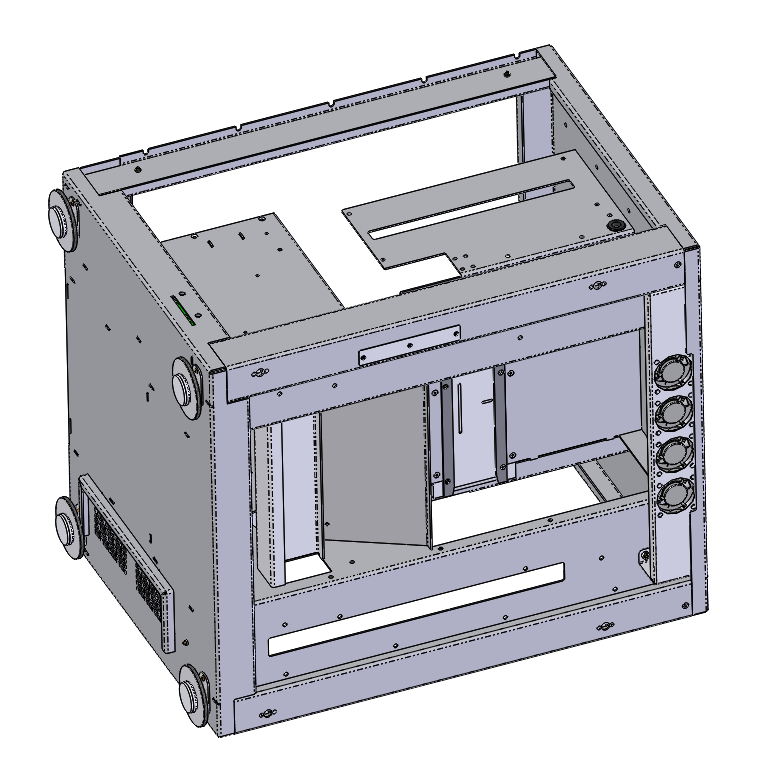

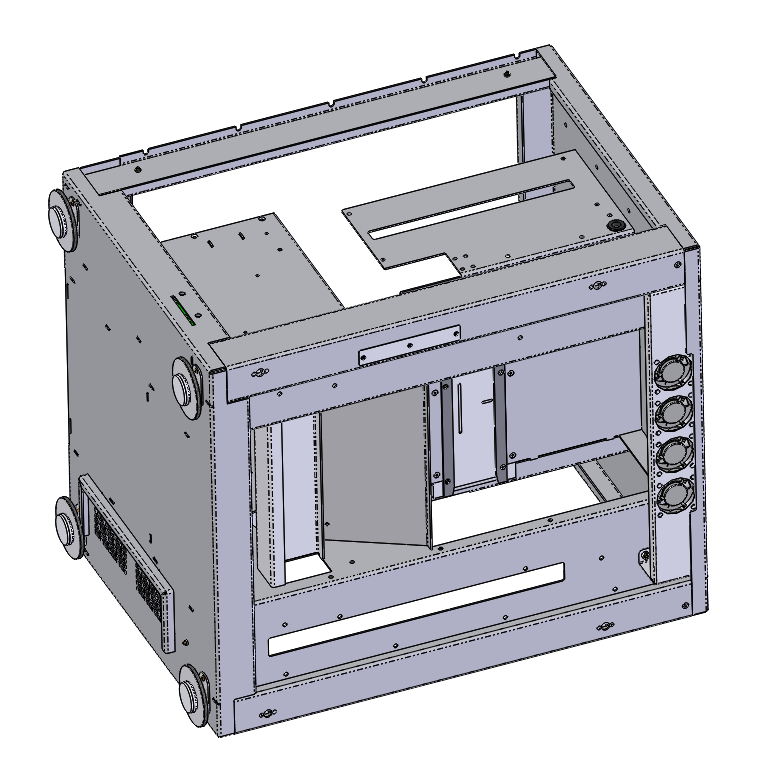

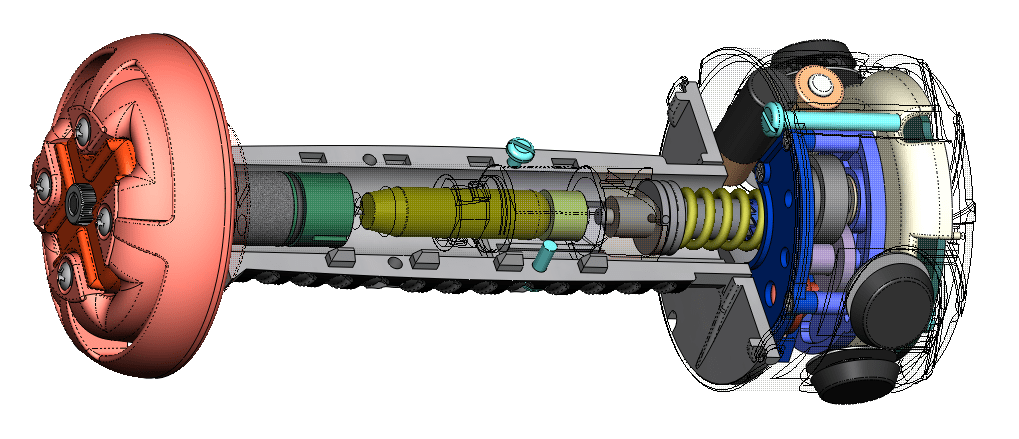

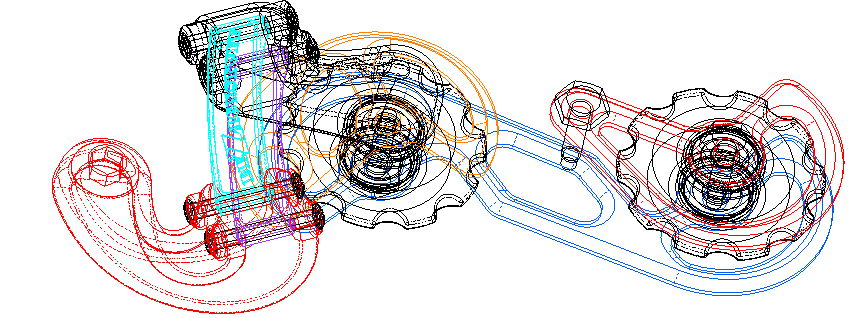

Color is something some engineers avoid.The model above is not just boring, it’s hard to see which parts are different from one another. You can tell they are all sheet metal, but sheesh. It’s a monochromatic wasteland. Color is capable of conveying a lot of meaning, but all of that is lost here. Boring, yes, but that’s not the point. It also misses the opportunity to communicate.

The use of color on a model does not mean you’re weak or trying to be artistic, or a closet marketing monkey. It means you’re visually organized. It means you have a system and can identify parts quickly, at sight. Color can be used in models to help you quickly and visually identify different types of geometry in parts and assemblies. You can even use colors in multibody models to help you identify faces that will eventually go into creating a particular body or area of the model. Visualization techniques can save you a lot of time, and if you standardize techniques across your organization, that savings will really accumulate. I know people have some very ingrained habits when it comes to color, and those habits don’t always have anything to do with productivity.

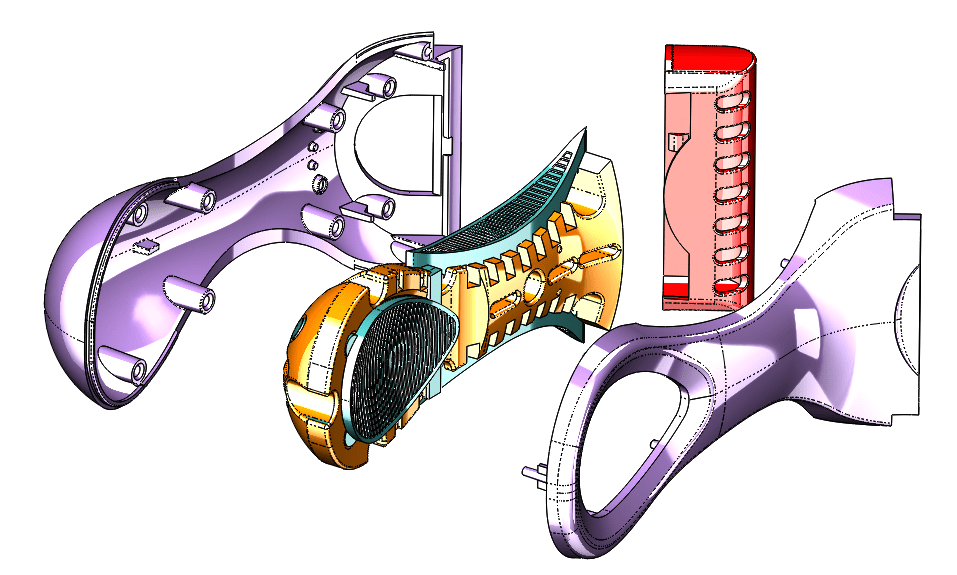

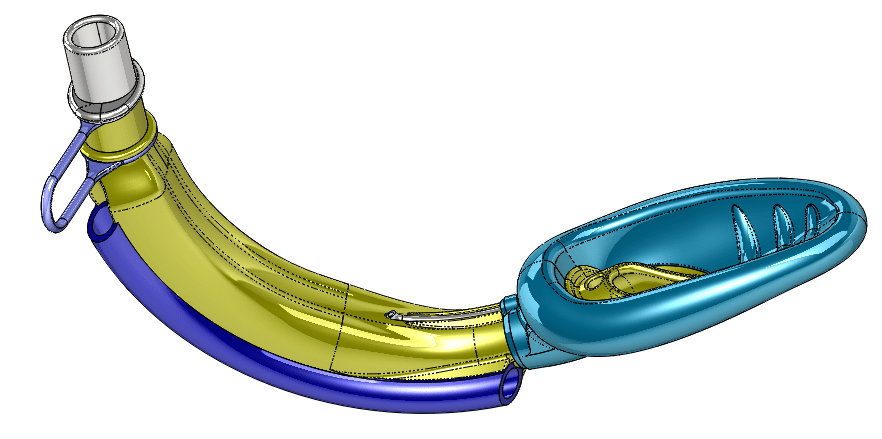

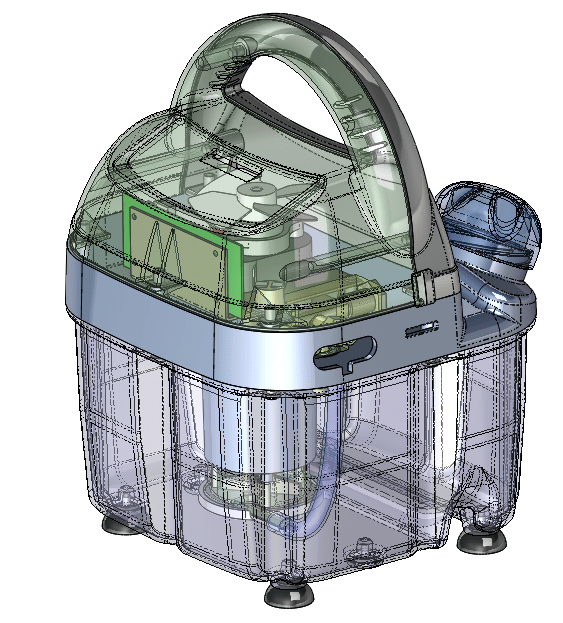

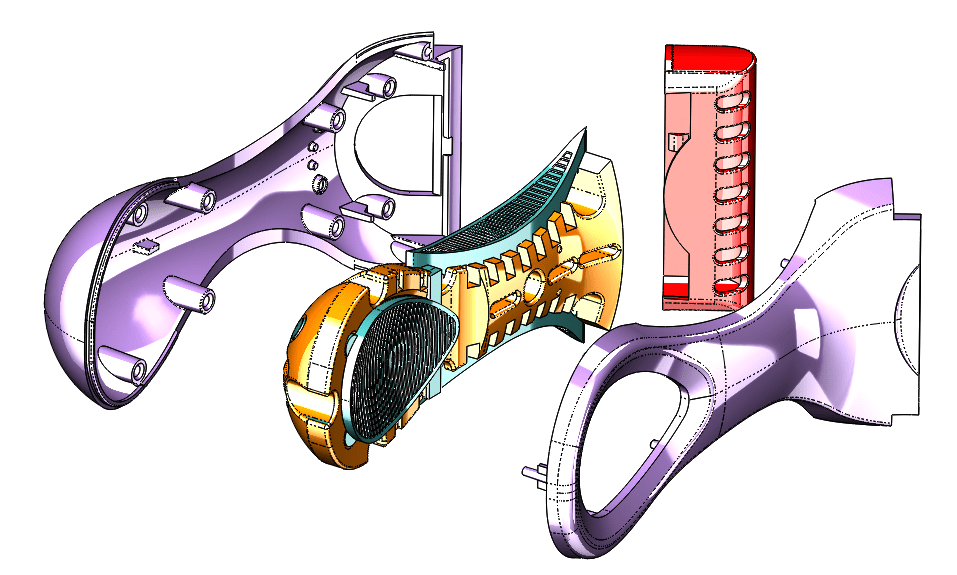

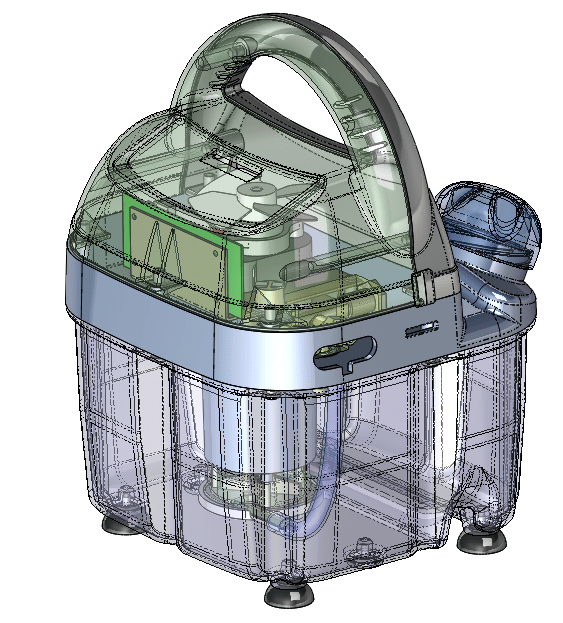

Colors used to identify different parts or materials on an overmolded insert part for a razor assembly.

Color is rarely used in the design phase to make parts look like they will in the real world. I have seen people make assemblies of all gray parts, and that drives me nuts. Color is an ally, it is your friend. You can use it to help you.

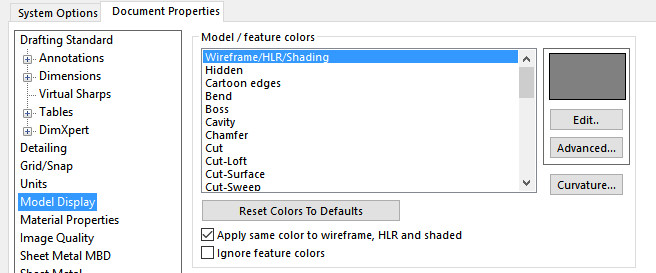

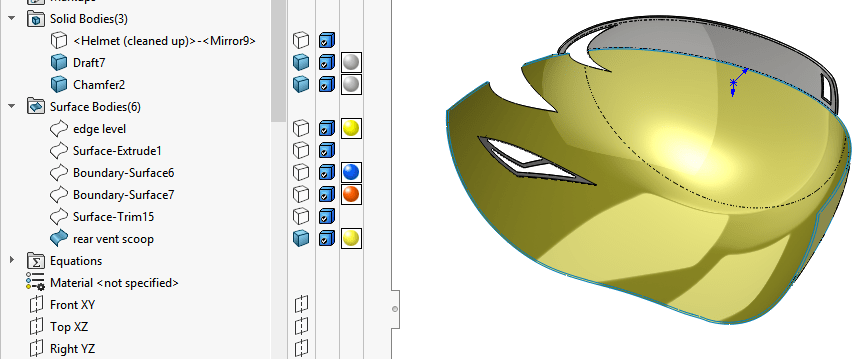

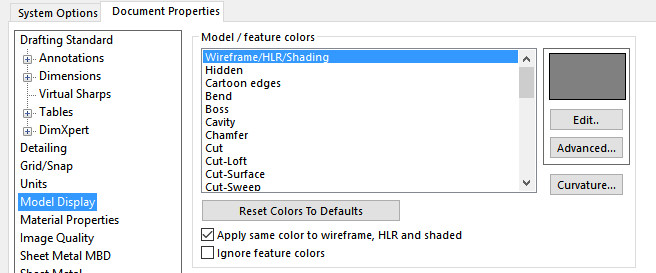

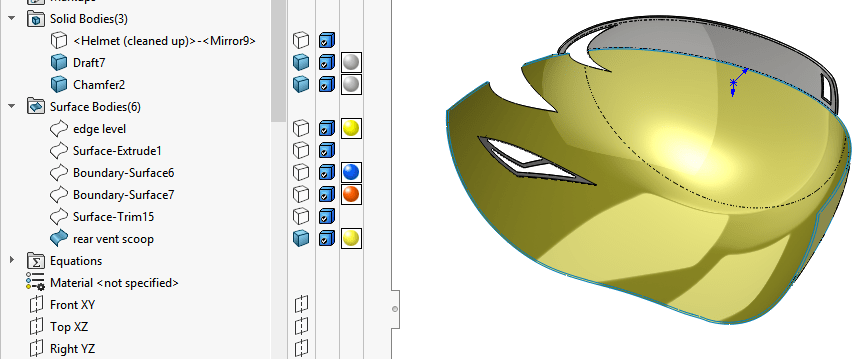

There are some settings In SolidWorks that I don’t see many people use in the Document Properties that allow you to automatically apply colors to different types of features. One of my favorites is to change any surface feature to yellow.

You can assign a specific color to derived (inserted) parts, holes or fillets. These are Document Properties, under Model Display, so the settings are saved in templates. If you use different templates for different types of parts, you can save the colors there, and have one color for sheet metal, one for machined, another for plastic, colors for purchased parts, or electronic components.

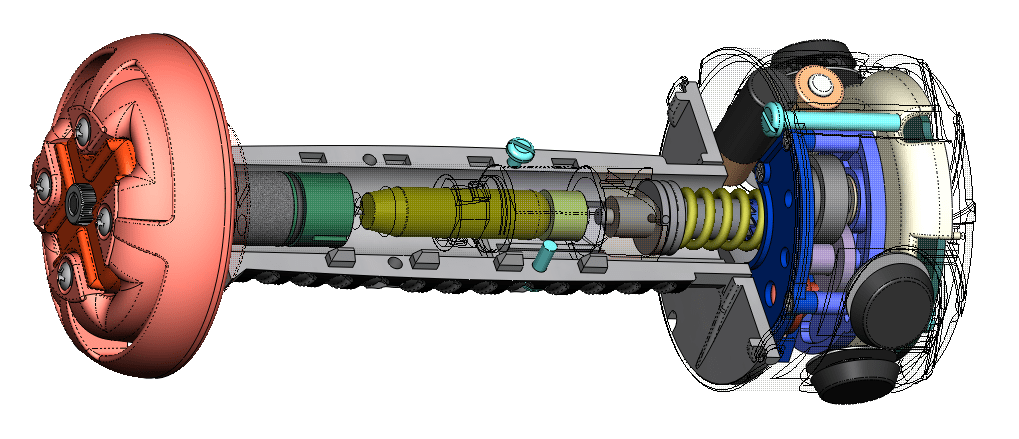

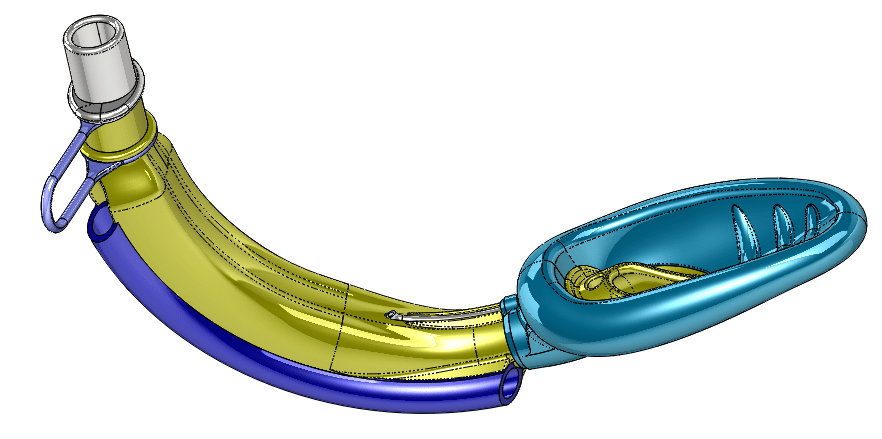

If you consider transparency and display type (wireframe/shaded), as well as model sectioning and exploded views, there are a lot of other things you can do to improve the visualization of your models, especially those with interior parts. Visualization is one of the easiest and most valuable things you can do with your 3D product data.

Color can also be used in evaluation and analytics. Stress analysis has always used color to categorize results. It was Paul Sr from Orange County Choppers who summed up his understanding of FEA by saying “Red is bad, blue is good”. That was a classic, but really true. Advanced selection uses color to sort parts by size. Color is used in draft analysis to help show draft angles of faces.

Zebra stripes, curvature analysis, draft analysis are all functions that make use of colors to help visualize analysis results.

One of my favorite tools for dealing with colors is the Display Pane. Display Pane works for both parts and assemblies, and it enables you to go to specifically the FeatureManager entry that you want to color, and see if it has any overrides or is using default colors. Access the Display Pane with F8. When you start using colors, this will be your best friend. Truly one of the best interface functions added to the SolidWorks software in a long time.

My technique for selecting colors is fairly random, but because I’m using colors to identify items, I tend to go for contrast. I know it offends a lot of people to look at models with wild contrasting colors, but I’m obviously not doing it for the aesthetics.

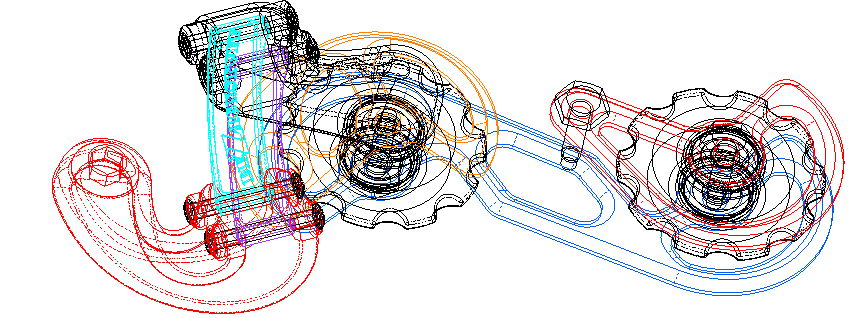

Color can also be used in wireframe and on drawings. Wireframe can be a better option than transparency sometimes if performance is a consideration. There is a setting (shown in the second image from the top) that forces SolidWorks to use the same color for wireframe display as it uses for color. This makes it easy when you use the Display Pane to switch from shaded to wireframe, because the parts all remain the same color. In wireframe, colored parts are much easier to select than strictly black edges.

My point here is that color is not just for making things look pretty, it’s for making things stand out, organizing things together, conveying information at a glance that you’d otherwise have to look at a table to get. Yes, you’re going to run the risk of offending your interior decorator types, but haven’t you been looking for a way to do that anyway? Color is functional. Use it and benefit.

Use of Color in Models

Color is something some engineers avoid.The model above is not just boring, it’s hard to see which parts are different from one another. You can tell they are all sheet metal, but sheesh. It’s a monochromatic wasteland. Color is capable of conveying a lot of meaning, but all of that is lost here. Boring, yes, but that’s not the point. It also misses the opportunity to communicate.

The use of color on a model does not mean you’re weak or trying to be artistic, or a closet marketing monkey. It means you’re visually organized. It means you have a system and can identify parts quickly, at sight. Color can be used in models to help you quickly and visually identify different types of geometry in parts and assemblies. You can even use colors in multibody models to help you identify faces that will eventually go into creating a particular body or area of the model. Visualization techniques can save you a lot of time, and if you standardize techniques across your organization, that savings will really accumulate. I know people have some very ingrained habits when it comes to color, and those habits don’t always have anything to do with productivity.

Colors used to identify different parts or materials on an overmolded insert part for a razor assembly.

Color is rarely used in the design phase to make parts look like they will in the real world. I have seen people make assemblies of all gray parts, and that drives me nuts. Color is an ally, it is your friend. You can use it to help you.

There are some settings In SolidWorks that I don’t see many people use in the Document Properties that allow you to automatically apply colors to different types of features. One of my favorites is to change any surface feature to yellow.

You can assign a specific color to derived (inserted) parts, holes or fillets. These are Document Properties, under Model Display, so the settings are saved in templates. If you use different templates for different types of parts, you can save the colors there, and have one color for sheet metal, one for machined, another for plastic, colors for purchased parts, or electronic components.

If you consider transparency and display type (wireframe/shaded), as well as model sectioning and exploded views, there are a lot of other things you can do to improve the visualization of your models, especially those with interior parts. Visualization is one of the easiest and most valuable things you can do with your 3D product data.

Color can also be used in evaluation and analytics. Stress analysis has always used color to categorize results. It was Paul Sr from Orange County Choppers who summed up his understanding of FEA by saying “Red is bad, blue is good”. That was a classic, but really true. Advanced selection uses color to sort parts by size. Color is used in draft analysis to help show draft angles of faces.

Zebra stripes, curvature analysis, draft analysis are all functions that make use of colors to help visualize analysis results.

One of my favorite tools for dealing with colors is the Display Pane. Display Pane works for both parts and assemblies, and it enables you to go to specifically the FeatureManager entry that you want to color, and see if it has any overrides or is using default colors. Access the Display Pane with F8. When you start using colors, this will be your best friend. Truly one of the best interface functions added to the SolidWorks software in a long time.

My technique for selecting colors is fairly random, but because I’m using colors to identify items, I tend to go for contrast. I know it offends a lot of people to look at models with wild contrasting colors, but I’m obviously not doing it for the aesthetics.

Color can also be used in wireframe and on drawings. Wireframe can be a better option than transparency sometimes if performance is a consideration. There is a setting (shown in the second image from the top) that forces SolidWorks to use the same color for wireframe display as it uses for color. This makes it easy when you use the Display Pane to switch from shaded to wireframe, because the parts all remain the same color. In wireframe, colored parts are much easier to select than strictly black edges.

My point here is that color is not just for making things look pretty, it’s for making things stand out, organizing things together, conveying information at a glance that you’d otherwise have to look at a table to get. Yes, you’re going to run the risk of offending your interior decorator types, but haven’t you been looking for a way to do that anyway? Color is functional. Use it and benefit.